TopVu® Readers and Tags For Dust Control

Fri, Sep 28th 2018

Underground mining is considered by many to be a dangerous occupation including health hazards. Today, mine operators are committed to the safety and health of their employees. Controlling the dust in the underground environment is only one of many issues mine operators struggle with in efforts of improving the conditions in which their employees are working in.

Mine X use water and improved ventilation as a primary source of dust control . Muck is kept wet and a water truck travels throughout the mine spraying water similar to what you would see on a construction site in efforts to control dust.

One of the challenges mine X encountered was that critical assets located throughout the mine was inadvertently sprayed with water resulting in a potential safety hazard and potential for lost production.

HOW

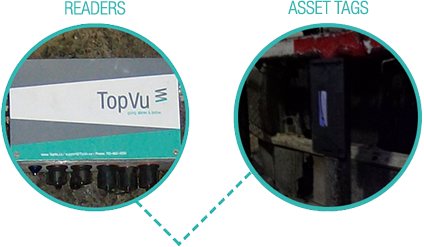

TopVu® Mine Hardened D-RDR Reader (active and passive) was installed on the mobile washer and zero maintenance RFID equipment tags was installed on critical assets such as a portable sub. The equipment tags require no power or communication infrastructure. This made the deployment of this system quick and low maintenance. When the equipment tag is detected, the pump on the mobile sprayer is automatically shut off until the zone in question has been cleared reducing the hazard of water in the area of a portable substation. Additional functions can also be easily integrated with minimal cost to the mine operators.

The TopVu® D-RDR includes additional features such as store and forward, leaky feeder and / or WiFi interface, the ability to read active and passive tags. These features could easily be used for increased functionality further enhancing the safety and efficiency in the underground mine . TopVu® Mine Hardened products can be integrated into a solution to solve many of the challenges found in mining.